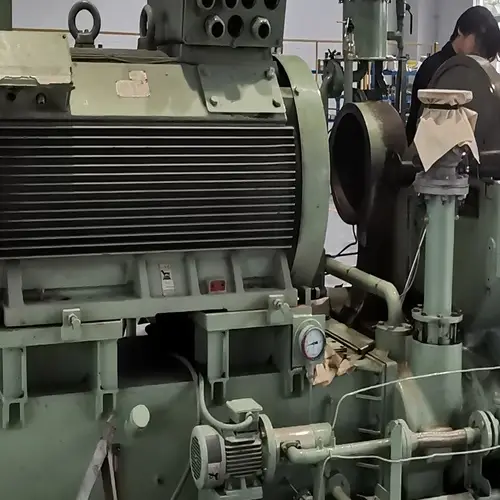

China Wholesaler Compressor for Filling Station

Product Description

The China Wholesaler Compressor for Filling Station is a cutting-edge product that combines the latest technology cooperation between China and Japan, ensuring high reliability. It features an Oil Cooling Permanent Magnetic Motor, which enhances its performance and efficiency. The compressor is designed with an IP65 protection grade and a heavy-duty air filter, making it suitable for use in high dusty environments. With its IE4 Efficiency motor efficiency, the compressor offers exceptional energy savings. It operates in the most energy-saving mode, only working at loading, which further enhances its efficiency. The wide frequency range of 25%-100% allows for flexibility in operation. The premium magnetic material used in its construction can withstand temperatures of more than 180ºC. The PM motor supplier from Italy ensures its reliability. With a direct taper connection, the compressor eliminates transmission power loss and facilitates easy maintenance. The touch screen PLC with preset running schedule provides intelligent control. Both the main motor and fan motor are inverter-controlled, enabling more accurate control. Installation and service are incredibly convenient. This compressor boasts fantastic energy-saving capabilities, saving up to more than 30-40% of energy consumption.

|

After-sales Service |

Engineers available to service overseas |

||

|

OEM |

Welcomed (we have 5 professional R&D engineers to do design & customizing service according to client’s different requirement) |

||

Application

The China Wholesaler Compressor for Filling Station is suitable for various applications, including filling stations for LPG and CNG, as well as in air compressor lowes.

Packaging & Shipping

Our compressor is carefully packaged to ensure safe delivery. We offer reliable shipping options to ensure prompt and efficient delivery to our customers.

FAQ

1. How can we guarantee the quality of the compressor?

We always provide a pre-production sample before mass production to ensure the quality meets our customers’ requirements. Additionally, a final inspection is conducted before shipment to ensure the compressor’s quality.

2. Why should you choose us over other suppliers?

There are several reasons to choose us as your compressor supplier. Firstly, we take full responsibility for the quality of our products. Secondly, we prioritize high-quality manufacturing to ensure customer satisfaction. Lastly, we ensure on-time delivery to meet our customers’ timelines.

3. What services do we provide?

We offer various delivery terms, including FOB, CIF, EXW, FCA, DDP, DDU, Express Delivery, and DAF. Accepted payment currencies include USD, EUR, AUD, and CNY. We accept payments via T/T, PayPal, and Western Union. Our team is fluent in both English and Chinese, ensuring effective communication.

4. Do you offer customizations?

Yes, we welcome customization requests. Our team of 5 professional R&D engineers will design and customize products according to our clients’ specific requirements.

5. What other products does EVER-POWER GROUP offer?

EVER-POWER GROUP specializes in supplying various industrial products such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in offering high-quality products, competitive prices, and excellent customer service. We also provide customization services, welcoming drawings and samples from our valued customers.

All the content of this page is from the Internet and is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are only suitable for after-sales purposes and are not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory for purchase.

Introduction to the Performance Characteristics of Cng Compressor

The performance characteristics of Cng compressors are as follows:

-

High Efficiency

Cng compressors are known for their high efficiency in compressing natural gas, allowing for faster refueling and increased productivity.

-

Reliability

These compressors are designed to be reliable, ensuring consistent performance and minimizing downtime.

-

Low Noise

Cng compressors are designed to operate quietly, reducing noise pollution in surrounding environments.

-

Compact Design

These compressors are compact in size, making them suitable for various applications where space is limited.

-

Environmentally Friendly

Cng compressors help reduce carbon emissions and contribute to a cleaner environment as natural gas is a cleaner alternative to traditional fuels.

Types and Characteristics of Cng Compressor

There are several types of Cng compressors available, each with its own unique characteristics:

-

Reciprocating Compressors

Reciprocating compressors use pistons to compress the gas and are known for their high efficiency and durability.

-

Screw Compressors

Screw compressors use rotating screws to compress the gas and are known for their smooth operation and low maintenance requirements.

-

Centrifugal Compressors

Centrifugal compressors use rotating impellers to compress the gas and are known for their high flow rates and compact design.

Advantages of Cng Compressor Made of Different Materials

Cng compressors can be made of different materials, each offering unique advantages:

-

Steel Compressors

Steel compressors are known for their strength and durability, making them suitable for heavy-duty applications.

-

Aluminum Compressors

Aluminum compressors are lightweight and corrosion-resistant, making them ideal for portable and outdoor applications.

-

Composite Compressors

Composite compressors offer a combination of strength, durability, and corrosion resistance, making them suitable for various environments.

Application of Cng Compressor in Various Fields

Cng compressors find their value and importance in various fields:

-

Vehicle Refueling

Cng compressors play a crucial role in refueling Cng-powered vehicles, providing a fast and efficient refueling solution.

-

Industrial Applications

In industrial settings, Cng compressors are used for various applications such as powering machinery and equipment.

-

Power Generation

Cng compressors are utilized in power generation systems, ensuring a reliable supply of natural gas for electricity production.

-

Natural Gas Distribution

For the distribution of natural gas, Cng compressors are essential for maintaining adequate pressure in pipelines.

-

Backup Power Systems

Cng compressors are crucial components in backup power systems, providing a reliable source of energy during power outages.

Future Development Trends and Opportunities of Cng Compressor Products

The future of Cng compressor products holds promising trends and opportunities:

-

Technological Advancements

Advancements in technology will lead to more efficient and environmentally friendly Cng compressors.

-

Increasing Demand

With the growing focus on clean energy, the demand for Cng compressors is expected to increase in various industries.

-

Expansion into New Markets

Cng compressors have the potential to expand into new markets, such as emerging economies with a rising demand for natural gas.

How to Choose a Suitable Cng Compressor

Choosing a suitable Cng compressor involves considering several key aspects:

-

Clear Requirements

Clearly define your requirements and specifications to ensure the selected compressor meets your needs.

-

Material Selection

Select the appropriate material for the compressor based on factors such as application, durability, and corrosion resistance.

-

Design Optimization

Optimize the design of the compressor to maximize efficiency, performance, and ease of maintenance.

-

Suppliers and After-Sales Service

Choose reputable suppliers who provide quality products and reliable after-sales service.

-

Cost-Effectiveness

Evaluate the overall cost-effectiveness of the compressor, considering factors such as initial cost, energy efficiency, and maintenance requirements.

-

Quality Control

Ensure the selected compressor meets industry standards and undergoes rigorous quality control processes.

Author: Dream